DataCan's patented shut-in tool is a pre-programmable, battery-powered, valve and drive that opens and closes a wellbore downhole.

By opening and closing downhole, the wellbore storage effects are eliminated, resulting in better data and saving oil and gas customers time and money.

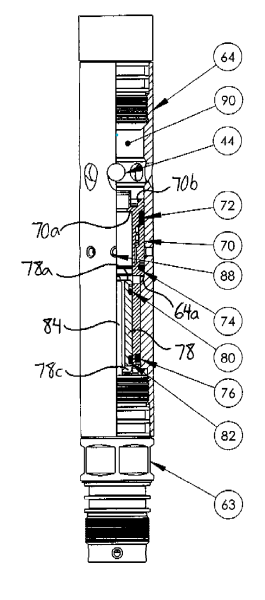

A high-temperature downhole motor and drive circuit is pre-programmed to turn on and off, the motor connects to a shuttle piston that activates a sliding sleeve. The sleeve floats and uses downhole pressure to close the production fluid flow instantly.

- Patented Instant Close Valve (US#7823633)

- Multiple Cycles

- 10,000 psi differential pressure

- 150°C and 177°C Drive Options

- 2-3/8” to 2-7/8” Valve = 1.135 square inch flow

- 3-1/2” and larger = 2.50 square inch flow

Downhole shut-in tools enable operators to shut in the wellbore downhole rather than at the surface, eliminating the “wellbore storage effects”. Wellbore storage effects are the result of long lengths of production tubing that need to be pressurized before the build-up can be recorded. The benefit of using a downhole shut-in tool is to allow for a quicker well build-up and better pressure data quality, saving operators money on downtime and giving reservoir engineers better data for their calculations.

Instant Close DataCan has a unique valve design that closes instantaneously giving the production engineer the best available pressure build-up data.

Multi-Cycle DataCan’s valve has the ability to re-open and close multiple times, this is necessary when reservoir engineers are performing three or four-point isochronal pressure tests. DataCan’s production and injection valve designs are patented in the United States and Canada.

High Temperature Use Our motor and controls circuit has recently operated in a production 151°C gas condensate well. This well is the highest field temperature DataCan has seen and is a milestone for shut-in tool operations. DataCan can confidently rate its drive section to 150°C. Further engineering is in progress to raise the operating temperature of the downhole shut-in tool to 165°C and higher.

Shock resistance The DataCan instant close / multi-cycle downhole shut-in tool is highly durable. Shut-in tools are often mounted below locks or plugs. As such, it is necessary that our valve and drive section are capable of withstanding the most physical of downhole conditions.

Drawdown and build-up tests are often performed on production and injection wells at regular intervals to monitor the performance of the producing formations in the well. A typical test setup usually includes a downhole valve (shut-in tool) which is placed in the well and manipulated by slickline.

There is usually a pressure recording device below the valve which records the pressure response of the formation being tested as the valve is opened or closed. The formation is allowed to flow for a sufficient length of time to ensure that it is drawn down to the desired level. After this draw-down period is complete, the shut-in valve is used to shut in the well. The formation pressure is allowed to build up, allowing the pressure to reach the desired level before another draw-down period is started. The entire process is sometimes repeated immediately to acquire more pressure data from another drawdown/build-up test.

The common sizes of valves are:

- 1.75” OD valve used for 2-3/8” and 2-7/8” tubing

- 2.5” OD valve for 3-1/2” and larger tubingAn important aspect of the downhole assembly is the connection from the valve to the lock mandrel assembly.

An important aspect of the downhole assembly is the connection from the valve to the lock mandrel assembly.

The lock mandrel is set inside the lock, below the lock mandrel is a crossover, below the crossover is the DataCan valve, below the valve is a set of memory pressure gauges. The connection from the valve to the lock mandrel assembly is typically performed with a mechanical equalizing sub. There are two common types of mechanical equalizing subs: a sliding sleeve and a Kobe knockout type. DataCan recommends using the Kobe knockout type.

In any case, it is important to know the exact size and type of lock mandrel that is going to run downhole. The mechanical equalizing crossover is customized to attach to each specific type and size of lock mandrel. There are two common types of lock mandrels, the Otis type, and the Baker type. In each type, there are a variety of common sizes, and each size is determined by the OD of the mechanical equalizing sub. Typical sizes are (in inches of diameter): 1.781, 1.875, 2.125, 2.188, 2.313, 2.56, 2.75, 2.813, 3.66, 3.81.

DataCan is able to manufacture a custom equalizing sub that will integrate directly into the top of the valve housing. The DataCan mechanical equalizing solution means that your crossover solution will have at least one less potential leak path. DataCan highly recommends using an integrated mechanical equalizing sub to connect the downhole shut-in tool to the lock mandrel.

References: