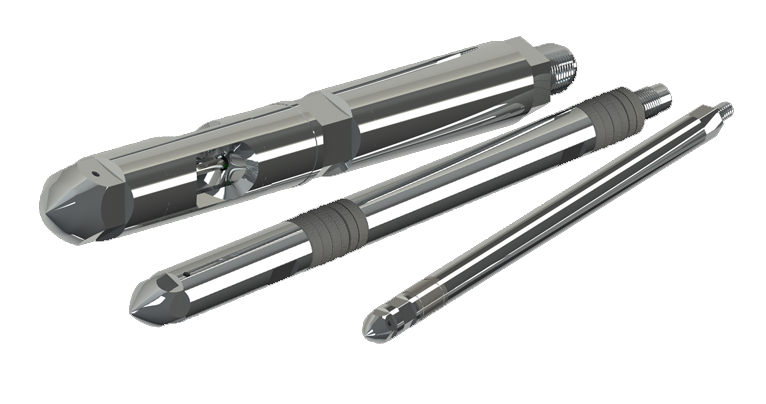

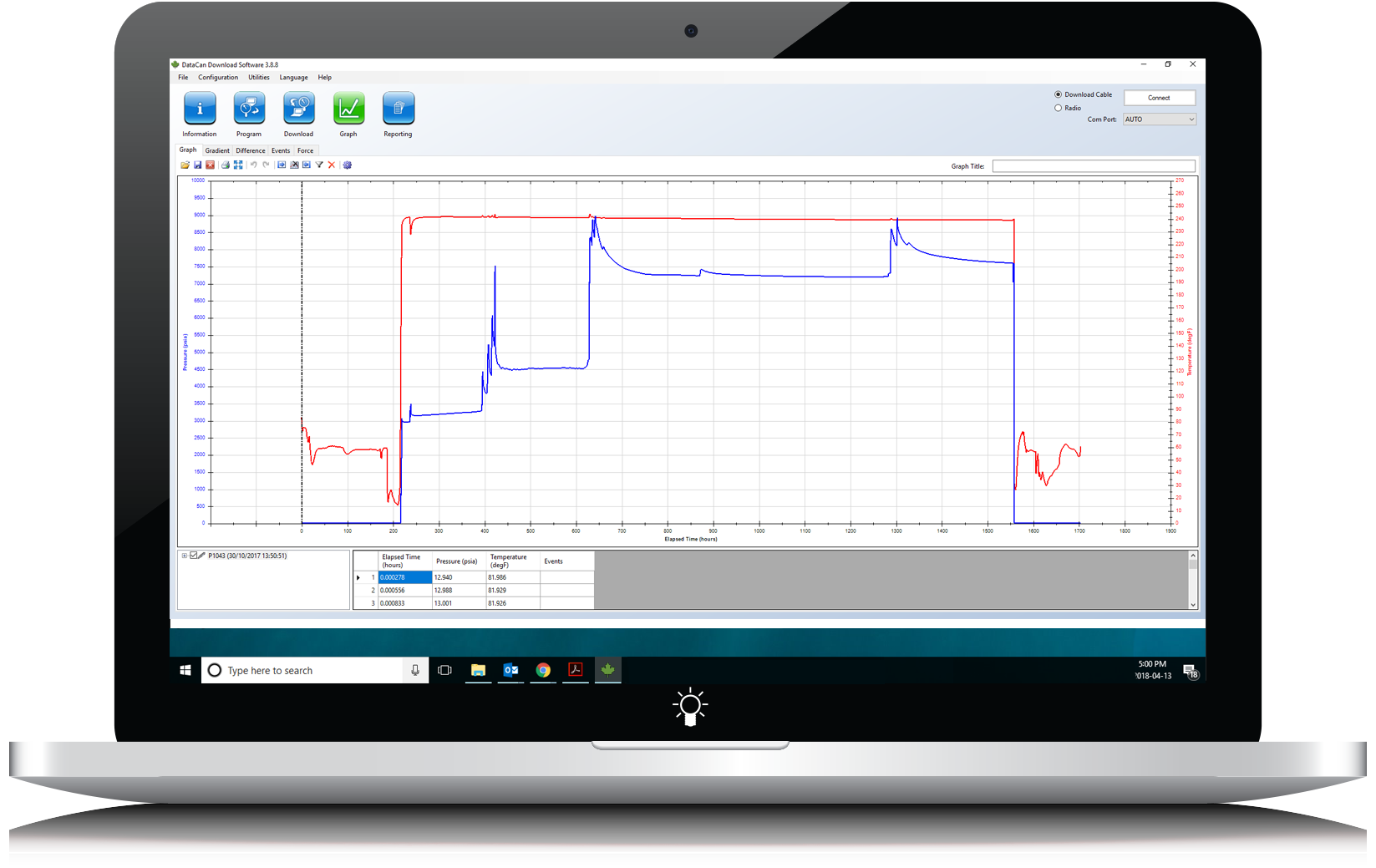

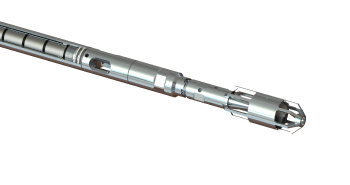

DataCan downhole memory gauges measure key parameters from a well such as pressure, temperature, and flow to increase your knowledge of the well’s performance and give insights into productivity improvements. Memory gauges can log data during surveys of a few hours, to pressure build-ups lasting months or years.

Downhole gauges are designed to survive the harshest of conditions, including high pressure, high temperature, and corrosive environments. Typical uses for memory gauges are oil, gas, and geothermal wells to determine fluid characteristics.

All DataCan downhole memory gauges use the same easy-to-use software to keep training to a minimum.

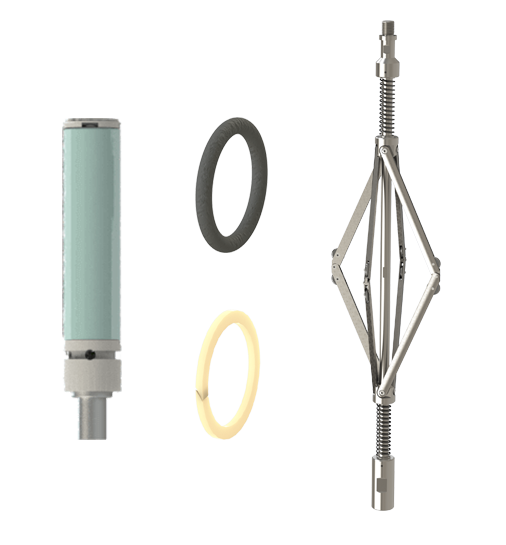

Standard and custom gauge carriers are available with or without added shock absorbers.

DataCan equipment is available to rent or to purchase. Contact your local or our main office for more information.

Applications:

- Gas lift monitoring

- Pressure build-ups/drawdowns

- Well testing

- Gradient surveys

- Pump monitoring

- Production Optimization

- Offset fracture and interference testing (DFIT's)

Deployment methods:

- Slick line

- Coiled tubing

- Carriers

- Gas lift mandrels

- Drill stem

- Jet-Pump Carrier

- Plunger Carrier

Want to read more information about downhole gauges? Schlumberger has a great oilfield terms glossary located here:

Schlumberger Oilfield Glossary Downhole Gauge Definition

For information about pressure gauges and their use in the oil and gas industry, try this link:

Schlumberger Oilfield Glossary Pressure Gauge Definition

Other search terms may include:

- down hole memory gauge

- down hole pressure gauge

- down hole pressure gage

- downhole pressure and temperature gauges

- downhole gauges oil and gas

- downhole gauges geothermal

- downhole temperature measurement

- downhole pressure measurement