Downhole Quartz Gauge Overview

posted on 15 January 2019 by James Wright

Choosing a quartz downhole gauge can be advantageous in certain situations. Quartz tools are more stable and have less drift than a Piezo tool. Typically you can go 2 years or more between calibrations with a quartz tool. Quartz tools are preferred for long-term high-temperature jobs.

- Downhole pressure and temperature measurement

- Pressure up to 30,000 psi maximum

- Accuracy of up to +/- 0.020% full scale

- Resolution of 0.00006% full scale

- Temperature up to 200 °C maximum

- Accuracy of +/-0.25 °C

- Resolution 0.005 °C

- 2 million data sets of memory

- 1 second to once a day sampling

All of DataCan’s quartz tools use hybrid oscillating circuits. Hybrid circuits are 100 times more reliable than standard surface mount (soldered) electronics.

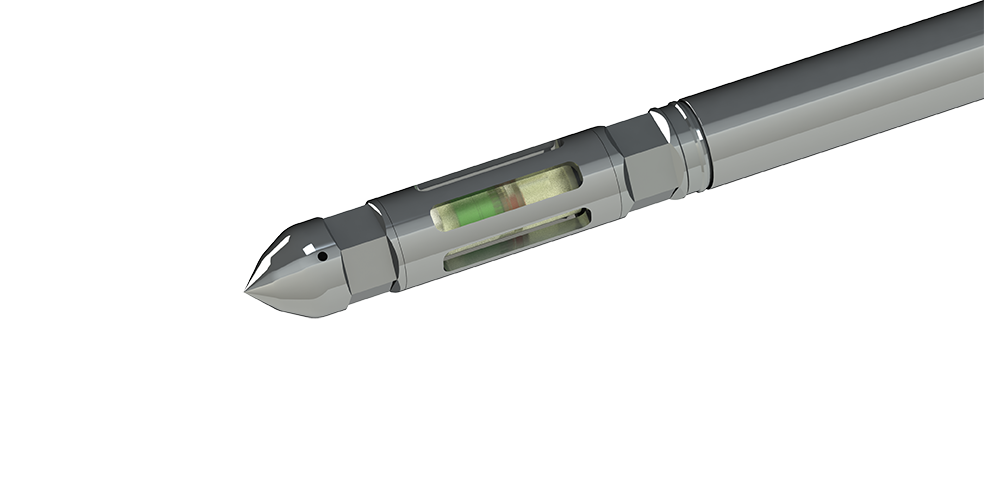

Hybrids, like the one above, have no plastic parts. The raw die is mounted onto a ceramic substrate. The resulting structure is much smaller, and will work reliably to higher temperatures (up to 225°C).

Using modular memory cartages means that DataCan’s quartz tools can be upgraded in the field. At any time, a DataCan customer can change the memory module out for a surface readout module.

DataCan’s mechanical package uses electron beam welding to reduce leak paths. DataCan has one tool joint, the competitions’ tools have up to three. As well as reducing the number of potential leak paths, DataCan has improved its seal joint. A common seal failure is an extrusion. DataCan’s seal design uses metal-to-metal bevelled seal to eliminate the extrusion gap.

Check out our quartz downhole memory pressure gauges, quartz downhole permanent pressure gauges, and quartz surface pressure transmitters.