Make tools that work and focus on the customer.

2006

DataCan was founded in 2006 by four engineers with experience designing downhole and surface pressure gauges, permanent monitoring systems, and other downhole logging tools.

We branded ourselves as "the next generation of downhole tools..." with these principles:

1) Customer Driven. DataCan is not solely concerned with filling the lines on a purchase order — we place value the entire customer experience. From product development through manufacturing, delivery, and after sales support we aim to deliver value and build trust with our customers by understanding and delivering on their needs and expectations. We succeed when our customers succeed.

2) DataCan, not DataCan’t. “DataCan, Not DataCan’t” embodies our belief in meeting challenges head on with optimism, determination, and creativity. This approach promotes taking initiative, staying resilient in the face of setbacks, and focusing on solutions rather than obstacles. This mindset inspires us to embrace opportunities and empower each other to turn challenges into achievements. It is not just about what we do, but how we do it — with confidence and a relentless drive to succeed.

3) Commitment to Quality. DataCan’s commitment to quality means striving for excellence in everything we do. It reflects our unwavering dedication to delivering superior products and services, while maintaining the highest standards in every aspect of our work. We prioritize attention to detail, continuous improvement, and reliability, ensuring that our customers can always trust that what we offer meets or exceeds expectations. This commitment is at the heart of our business and drives us to not only meet industry standards but to set them.

4) Bump the Lamp. Inspired by Disney's lamp-bumping tale, we embrace the ethos of pushing boundaries. Like the unexpected swaying lamp that revolutionized animation, we aim to surprise and delight our clients, propelling technology forward rather than settling for good enough. Whether through groundbreaking designs or exceptional service, every team member is encouraged to "bump the lamp."

5) Winning with Integrity. Winning with integrity means achieving success while adhering to strong ethical principles and values. It emphasizes honesty, fairness, and respect for others, ensuring that victories are earned through hard work, transparency, and responsible behavior. It is about doing the right thing, even when no one is watching, and resisting the temptation to cut corners. It's about balancing ambition with moral character, ensuring that success is not just about the outcome but about the way in which it is achieved.

2007

Using James’ basement, DataCan began to design and create a new line of downhole tools. We started with the 1.25” piezo memory pressure gauge and an instant close multi-cycle patented downhole shut-in tool.

2008

Following the shipment of our first 200 gauges to the Middle East, we developed our quartz memory gauge, and our single channel surface logger.

2009

In 2009, we moved the ping pong shipping table and our noisy calibration system out of James' house into a small 1,500-square-foot commercial space. We also commercialized our piezo permanent system with our first installation in Syria and improved our developed the welded mechanical design for what would be our P3 line of gauges.

2010

In 2010, revenue continued to double and we created the digital chart recorder and designed geothermal flasks for our memory gauges. Permanent installations were completed in the USA and Australia.

2011

This year, we completed the prototype burst gauge. A high-speed sampling downhole pressure gauge designed to monitor perforation events. We also placed 230 P4 gauges into the Bakken for long term memory pressure monitoring

2012

By now had built over 2600 total gauges with over 110 permanent gauges installed globally. We added vibration measurements to our gauges and placed our quartz memory gauges into long-term high-temperature fields including the North Sea, South Texas, and Saudi Arabia. 54 More Permanents were installed with new customers in China, Russia, Europe, and Cuba. For the first time, we didn’t double our revenue.

2013

This year, we developed our multi-gauge permanent and wireless surface data platform adding another 46 permanent installations. We had a record quartz memory job, capturing 108 days of data at 315°F.

2014

We introduced our multi-channel surface logger and side pocket gas lift gauges, adding 59 permanent monitoring systems.

We moved into our custom-built 15,000 sqft facility.

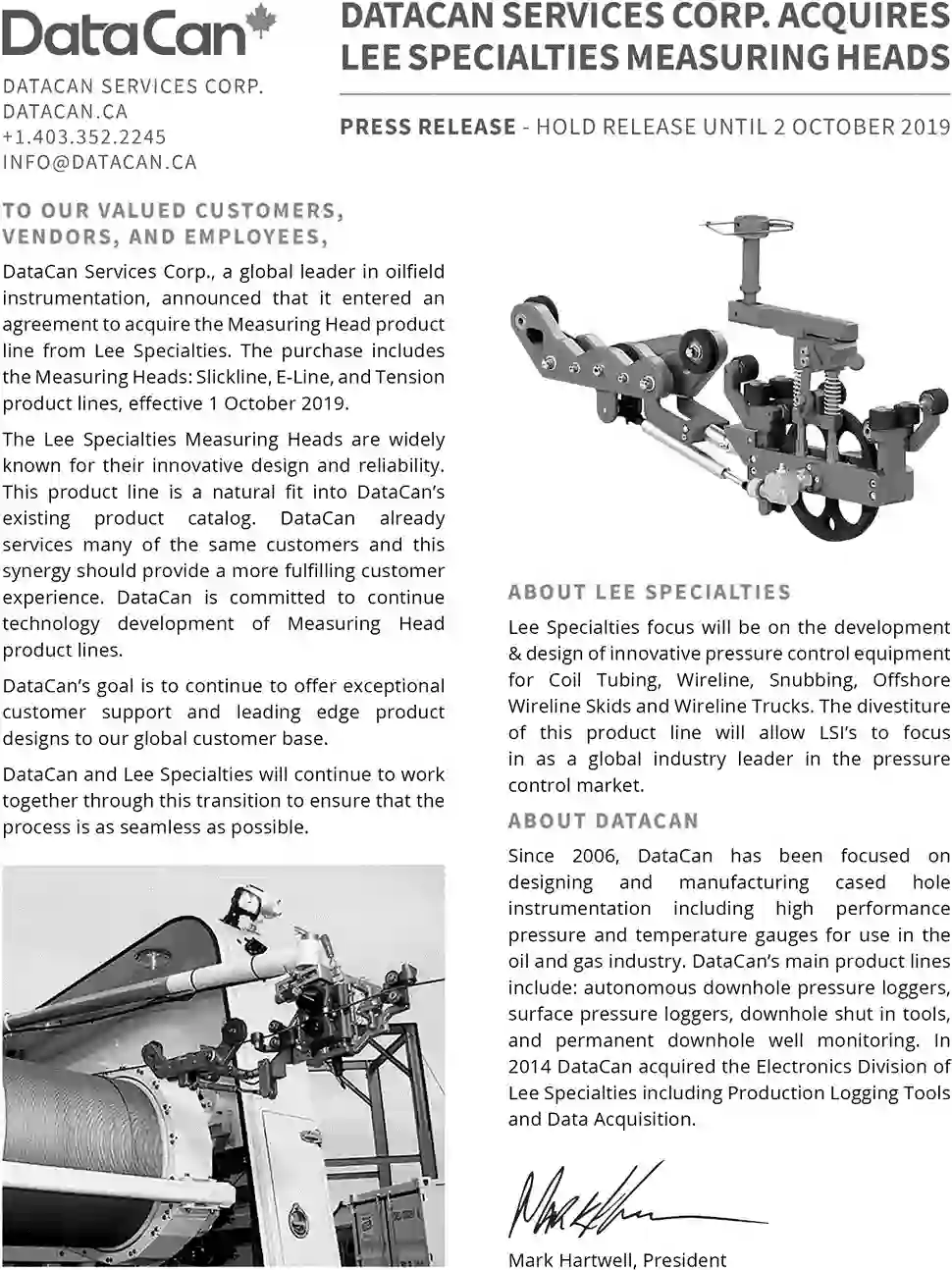

DataCan purchased the Electronics division of Lee Specialties, including their 1.375” OD Production Logging Tool, Linewise depth measurement systems, and Premier logging software and acquisition system.

2015

66 permanents were installed including our first systems in Venezuela.

2016

61 More permanent systems installed.

2017

In 2017, DataCan Services Corp., received its ISO 9001:2008 certification

DataCan upgraded the Lee Memory Production Logging Tool section from 150°C to 177°C. And completed our first high temperature (177°C drive) Down Hole Shut In Tool (DHSIT) job, and our first injection specific DHSIT job.

DataCan USA, Ltd is formed and begins offering local service and support out of Houston Texas.

2018

Investment in a local service and support center in Houston is rewarded. DataCan USA, doubles its revenue in the second year of operations.

2019

DataCan purchases DataWise Monitoring Systems Corp., a USA based corporation that focuses on the sales and installation of Exact Downhole Pressure Monitoring Systems and Fiber Optic monitoring systems in Vietnam. PT Starluck Enterprises is wholly owned by DataWise and offers similar products and services in Indonesia.

DataCan is awarded Red Deer Canada’s “2019 Business of the Year”.

2019 Business of the Year Article

DataCan adds to its product catalog and acquires the Measuring Head product line from Lee Specialties.

DataCan USA, commits to field support service for its US land operations. Casey Bechdol brings his 20 years of downhole monitoring experience.

2020

DCUSA purchases a 5,000 sqft commercial facility at 14237 Aston St. The facility comes with a CNC machine shop.

2021

Lisa McRae joins the DataCan team, enhancing our local sales, support, and services in Australia and Southeast Asia.

DataCan USA, successfully installs a 10-gauge multi-gauge feedthrough packer system, the highest number of DataCan permanent monitoring gauges on a single TEC wire in DataCan’s history.

2022

This year, oil prices are rising and global demand for our products is accelerating. We released McForcey, a coil tubing-specific memory gauge that measures tension and compression. We also brought to the market an intelligent frac ball that measures pressure and temperature.

The Owners

|

Mark Hartwell, President Mark Hartwell is the President of DataCan and resides in Houston, TX, where he leads DataCan USA operations and supports local and international opportunities. He holds a B.Sc. in Mechanical Engineering and enjoys seeing projects and products through to commercialization. He travels extensively, working with customers to continuously improve DataCan’s product performance. |

|

Brad Pound, VP of Operations Brad Pound is the Vice President of Operations for DataCan. He has a B.Sc. in Electrical Engineering and has over 20 years of experience in the design of downhole electronics, systems, and packages. Brad is responsible for operations systems integration and production quality. |

|

James Wright, CEO (DataCan Canada) James Wright is the CEO, CFO, and CTO for DataCan Canada. He has a B.Sc. in Computer Engineering and has been designing downhole instruments for over 20 years. An active community participant, James is a past Board Chair for Habitat for Humanity Red Deer. James is currently taking the Executive MBA program at Haskayne School of Business in Calgary, AB. |

|

Sheldon Nadeau, Director Sheldon Nadeau is a Director of DataCan and plays a large role in Business Development and product growth. Sheldon has a B.Sc. in Mechanical Engineering and has 20 years of experience in the manufacturing and engineering of downhole tools.

|